| Jet Pulverizer | ||||||||||||||||||||||||||||||||||||||||||

+ Fluidized Bed Classifying Jet Mill + Precision Air Classifier + Classifying Impact Mill + Abrasive Powder Classifying Jet Mill/ Shaping + Bag Collector + Ultrafine Powder Processing Line

|

|

|||||||||||||||||||||||||||||||||||||||||

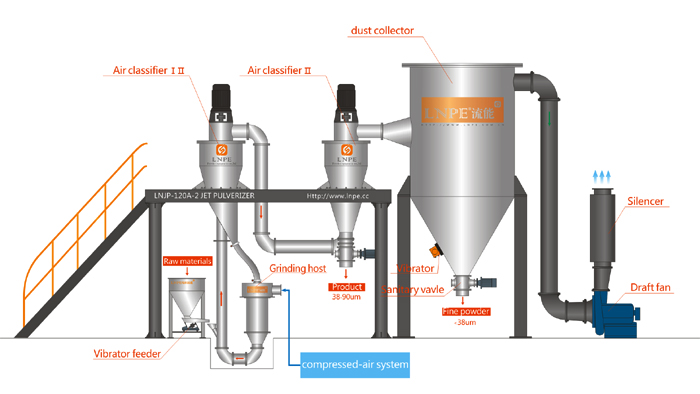

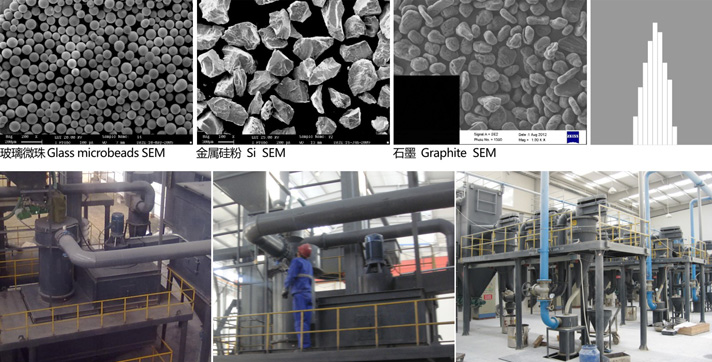

| LNJP New Jet Mill and Classifier is a newly grinding classifier( patent product)for coarser particle, specific size requirement, and high yield material, with advantages of high output, lower energy consumption, particle size concentrating distribution, it is widely used glass beads, metallic silicon powder, graphite powder etc. 1.Fluid dynamics software is developed by our independent R&D, calculated the perfect flow and ideal pressure distribution, combined the advantages of fluid dynamics technology and crushing strength control technology, greatly improve grinding efficiency and reducing energy consumption. 2.High capacity:compare with other grinding machine,the output of this equipment has improved 8~15 percentage. 3.Low energy consumption: Low energy consumption power, saving 40% over the equipments 4.Wear-resistance, secondary air entry keeps the cleaning flow stability, greatly reduce the wear. |

||||||||||||||||||||||||||||||||||||||||||

| ■Application field | ||||||||||||||||||||||||||||||||||||||||||

| Apply in requirement for the specific granularity and high yield material. Glass beads, metallic silicon, graphite etc... |

||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||

| ■Main technical parameter | ||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||